Final Project

layout: post title: 12. Final Project —

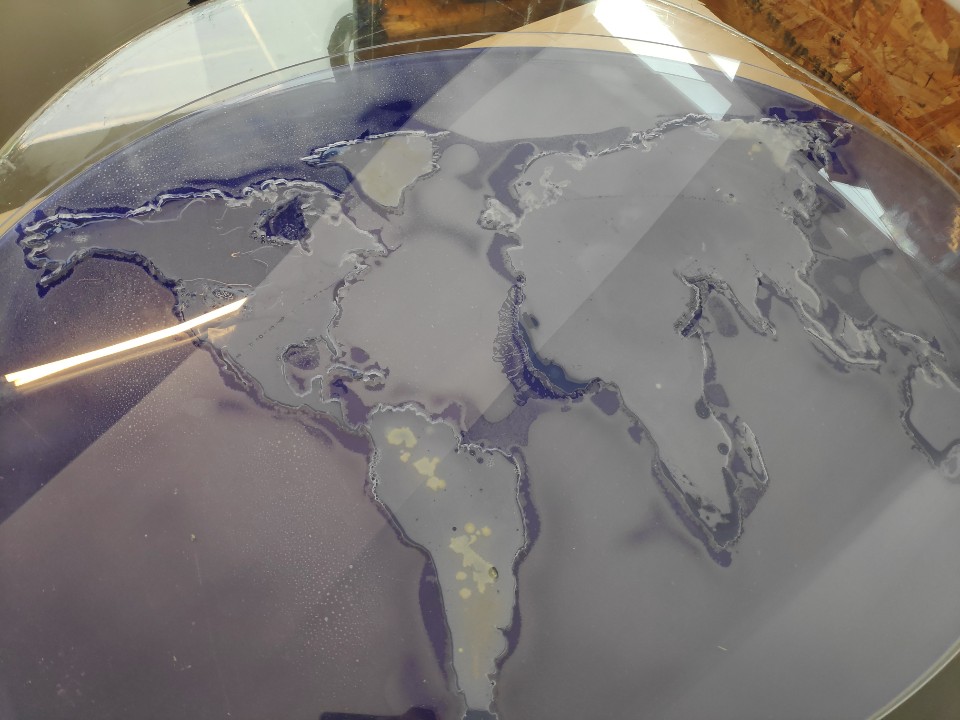

Making the world’s largest petri dish and simulating a world war

The original plan was to grow a mosquito under a controlled setting, select an ideal specimen and allow it to feed on me and then encase it alive in some melted amber, mold it into a ball shape and sand it to a clear finish and attach it to a cane, drill a hole in the said amber, and then extract the blood and replicate using a thermocycler, then storing it in close proximity to some radioactive material to encourage further mutation by errors from replication and mutagen exposure, but since I started this long run on sentence with the phrase, ‘the original plan was…’ that means that was not what happened.

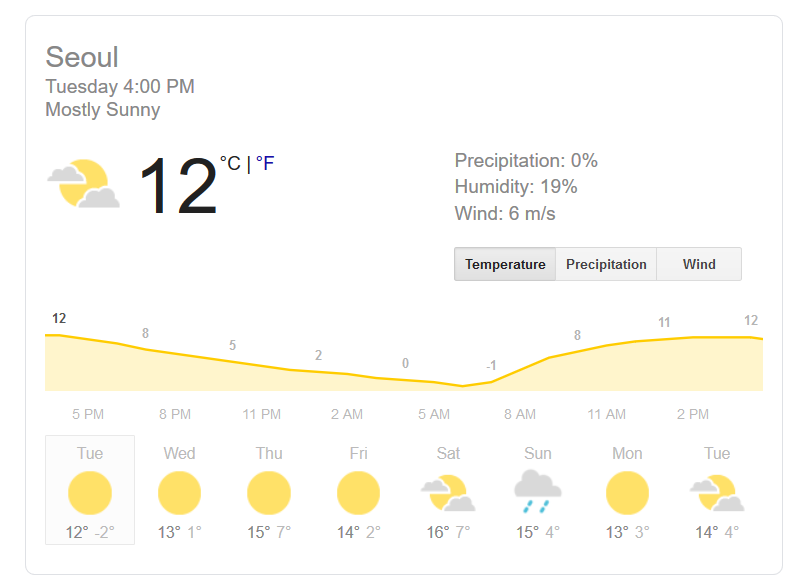

Due to humanity’s inability to prevent climate change, we suffered from negative celcius temperatures throughout the last few weeks, and even today is projected to be -2 (28F in freedom units) at night. This unexpected 3rd winter in mid March has prevented proper growth of the mosquitos nor even the chance to capture one in the wild (the only time in my life I actually wanted mosquitos earlier in the year). So although the initial plan to measure an increased mutation incident compared to spontaneous mutations (about a rate of 1 in 10^5 to 10^8) was a cool plan and I will pursue when the weather gets warmer, I am forced to delay this plan.

So we move on to our backup plan of world domination. Kinda cliche, I know, but its a traditional plan with a bit of a twist. I got my inspiration from some games like a board game called Risk and an interactive game called Plague. Both rely on using strategy to take over the world or at least the most area while fighting against other players or the game that is trying to prevent you from expanding. So by introducing bacteria as the intelligence behind the players, they will strive to conquer the world. Bacteria growth patterns have fascinated me ever since I’ve seen them create links that are the most efficient between nodes, which can represent intercity traffic routes or even slime molds that seek out food in mazes.

By making a petri dish that is in the shape of the Earth, I created a medium where bacteria can grow inside the continents. By growing different bacteria and molds and observing their growth, we have an interesting way to see how the microbes will grow in consideration of the geography as well as competing with other sources. However, an even more interesting way is to make it big. Bigger than anything ever made in the history of human civilization. So I checked online what the current record was. Lo and behold, some how the record doesn’t exist yet!

Hence my attempt to set a Guinness World Record on my own. It seems like a ridiculous thing to do yet requiring some expertise, hence something a mad scientist would do.

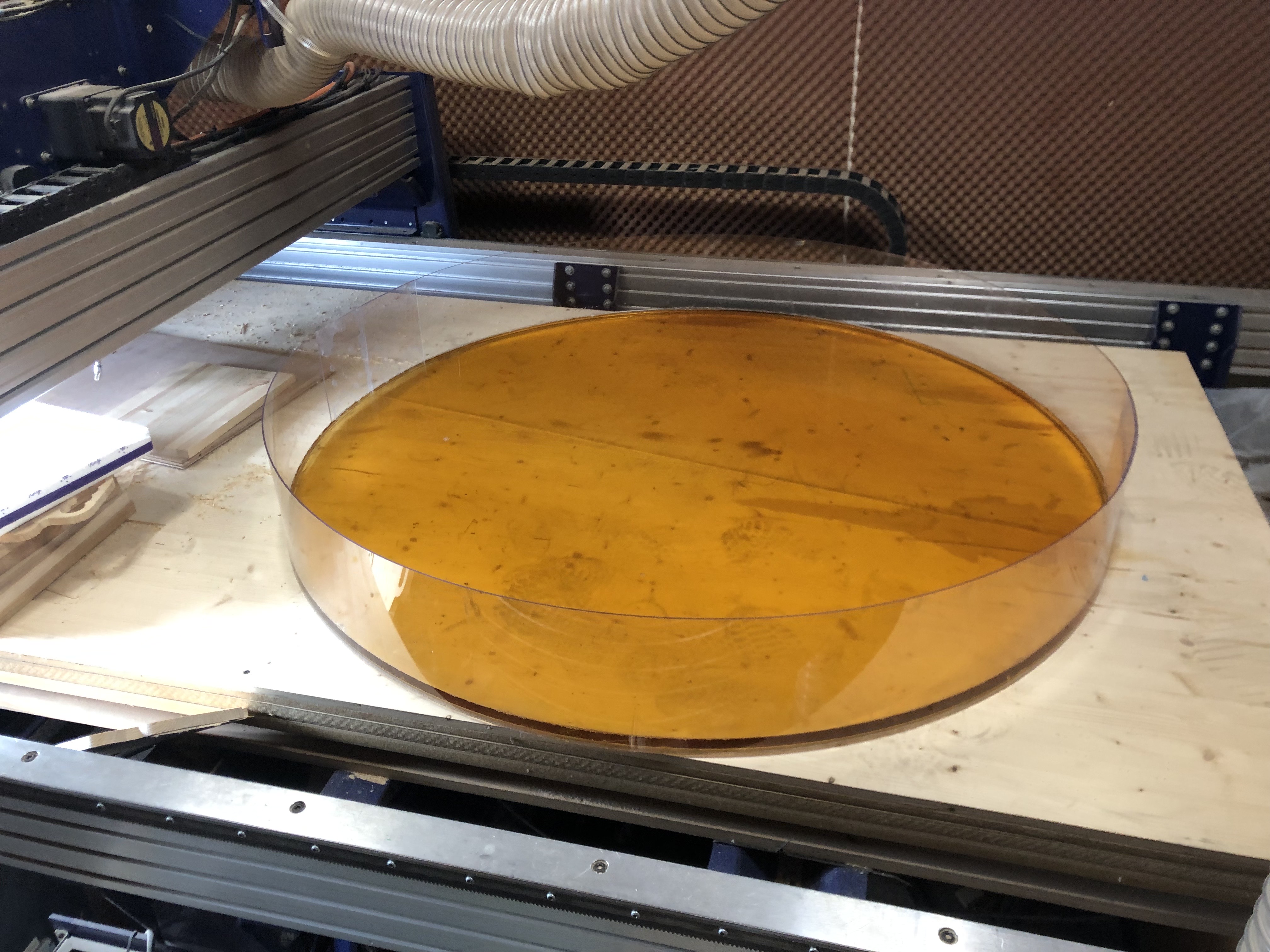

So from the official website, Guinness states that the petri dish must have several conditions to meet: be bigger than 1 meter for the diameter of the petri dish while maintaining the same wall height ratio, be transparent, and be usually made of glass or plastic. I also challenged myself to make it as functional as a normal petri dish, meaning it will be used to grow bacteria at the very least.

First off, a normal petri dish is 100mm diameter with a 15mm height. I wanted a 1200mm or about 1.2m long diameter with a 180mm height wall and a . I think going 20% percent over the goal is a good engineering concept and I also like the number 12 since I was born on December 12th at 12’o clock (fun story about my mum getting a c section at that time cuz she knew I would appreciate it, which I immensly do). So that gives me about a 144 times bigger petri dish than normal. Cool.

I chose acrylic or plexiglass to make the petri dish as polystyrene is the main component for plastic petri dishes which is a chemically bonded monomer styrene that is a very close material to acrylic, where hand crafted acrylic is actually stronger than polystyrene for most applications expect for having a lower melting temperature, which is the reason polystyrene is used since autoclaving application require higher heat resistance. They also share similar anti bacterial properties which will be very useful and they can be cut using the laser cutter. For the walls, I chose polycarbonate which is another transparent thermoplastic polymer similar but is more expensive with much stronger capabilities, even being used to make bulletproof glass. It was the ideal choice even though I was using a different material as PC allows itself to bend without breaking when thin enough. The only drawback is that polycarbonate can release toxic gases when melted so only physical cutting methods can be used.

Source: https://www.creativemechanisms.com/blog/eleven-most-important-plastics

Source: https://www.creativemechanisms.com/blog/eleven-most-important-plastics

I now have the dimensions and the materials, but I did not take into account accessibilty and feasibility. Turns out no one really needs giant polymer sheets and the largest standard size available to consumers is a 120cm x 80cm sheet sizes for most polymers. So I had to make them the right size. I got some 12mm thick acrylic sheets and cut half circles (605 radius, 5 extra for walls that are glued on top) in the lasercutter and put them together using chloroform which acts as a kind of welding agent rather than a gluing agent (gluing process would be using the glue to add material that bonds it while welding is melting the existing material to each other) (btw, putting choloform on a rag and putting it in your nose and mouth does not actually knock you out, you need to directly sniff the vapors for about 4.5 minutes, depending on your body weight) (yes, I checked myself).

After that I cut two bands of 5mm polycarbonate sheets to a length of 1900mm x 180mm for the walls. I had to then bond the two strips together using two smaller strips to kind of ‘band-aid’ them together and form a wall which I then placed and taped on initially to the plate. After affixing the walls to the right position, I used methylene chloride (don’t sniff anything that literally has the words meth in it) which can luckily bond PC to acrylic together which solved the issue of using two different materials.

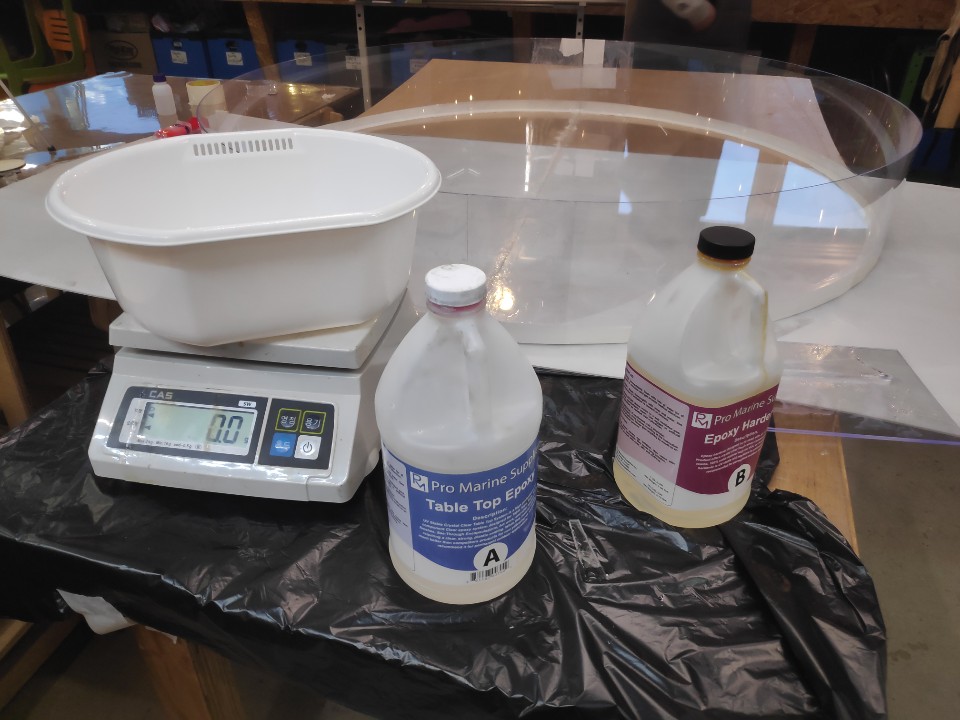

However in order to make sure that this petri dish would not break those welds just from shear forces or because of its own weight and to guarantee it being water tight, I used table top epoxy resin as a finisher. The resin I used was very reliable (read: expensive) as it would be cast clear, be waterproof, and naturally antimicrobial. I used about 0.6 gallons of activated resin as that’s about 2299.8009595 militers or cubic centimeters of volume to fill the plate up to 2mm in height in the plate.

After that I let it set for at least 48 hours and took of the tape.

Technically I am not yet finished to submit my world record as I to need a lid. The problem is that after I calculated several variables such as the mass of the lid material weighing down, if the same method of bonding would hold the lid suspended, if any unacceptable levels of sagging in the middle of the lid might occur, if the walls can support the weight, etc, etc I found that I need to get a single circlular sheet of PC around 3.4mm thick and diameter of 1220mm. Which is not available to consumer level purchasing. So I had to custom order it from a company outside Seoul and unfortunately at the day of the presentation it has not arrived. I still am comitted to applying to the Guinness World Records so I will have to wait until it arrives. I guess this is the reason no one really made a meter diameter petri dish before.

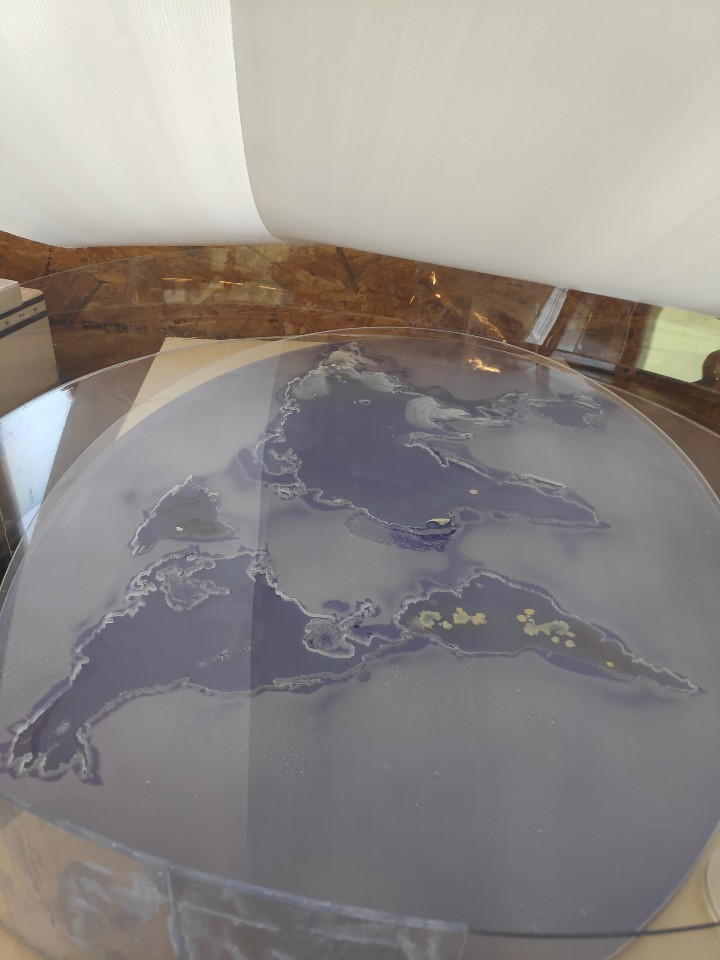

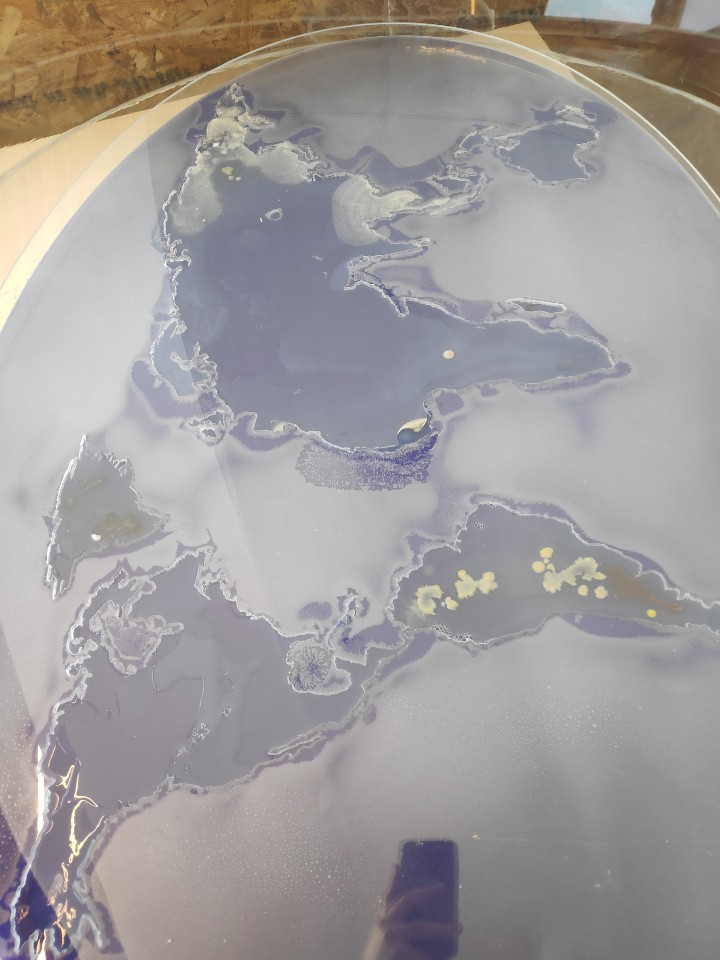

Moving on I needed to make a world. As the late and great Stan Lee said, “The best way to rule the universe is to create it” I created a flat earth and laser cut an oblong globe and glued the continents on top of it to create a height difference for the medium ti be poured into (I know the world is round and I know Antarctica is missing as well as some important landmasses but for the sake of representation of a game I had to make it simpler).

I made the oblong shape 1200mm in longest radius and 830mm in the shorter radius as that was the size limitation the lasercutter could cut at once. I realized at this point I could have probably gottent away with just making this instead of the giant petri dish, but then why would I be called a mad scientist?

Moving on, we now have to disinfect it before we can pour in the medium. Initially I wanted make a sterile hood big enough to for the plate but after doing some math, I found out the blower fans would be too loud to use for hours indoors so had to regretably forgo that plan. Also autoclaving was not really an option, although I did look at some resturant rice cooker equipment that cooks 200 servings of rice at once, but it was not a sealed pot and I didn’t want to risk making a large IED pipe bomb since that is frowned upo by many governments and I promised my dad I wouldn’t make anymore explosives ever since the high school Incident. So I looked into chemical and UV disinfection methods suitable for my materials. I used all the methods available possible, starting by soaping down the plates and then wiping using a bleach mixture of 10/90 sodium hypochlorite to distilled water, then spraying some 20% hydrogen peroxide and letting air dry, and then lastly going over the plates for at least 25 minutes on every area of the plates using an UV disinfection bar made for kitchen plates while running 3 HEPA filter fans full blast.

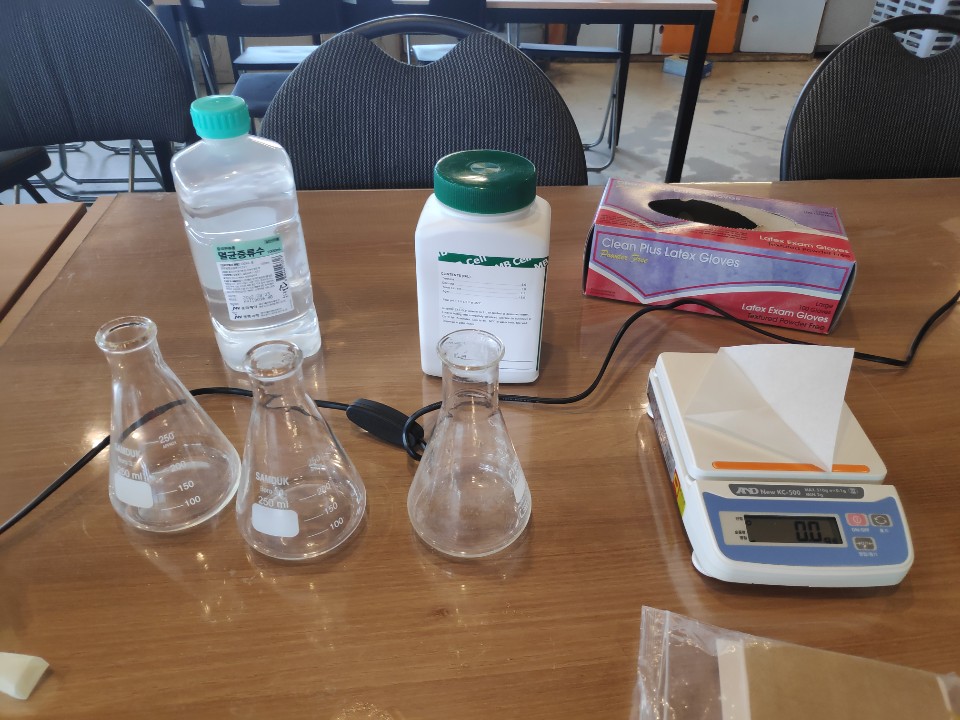

After that I placed some temporary but disinfected with the same process sheets to cover it and then made my agar medium. I used plate count agar as it not as selective as other agar mediums and it was the only other one that had enough to fill up my plates. The bacteria I planned to use was diverse and there wasn’t that much study behind some of them so it would be difficult to say that it was the ideal medium but I’m hoping it will be acceptable.

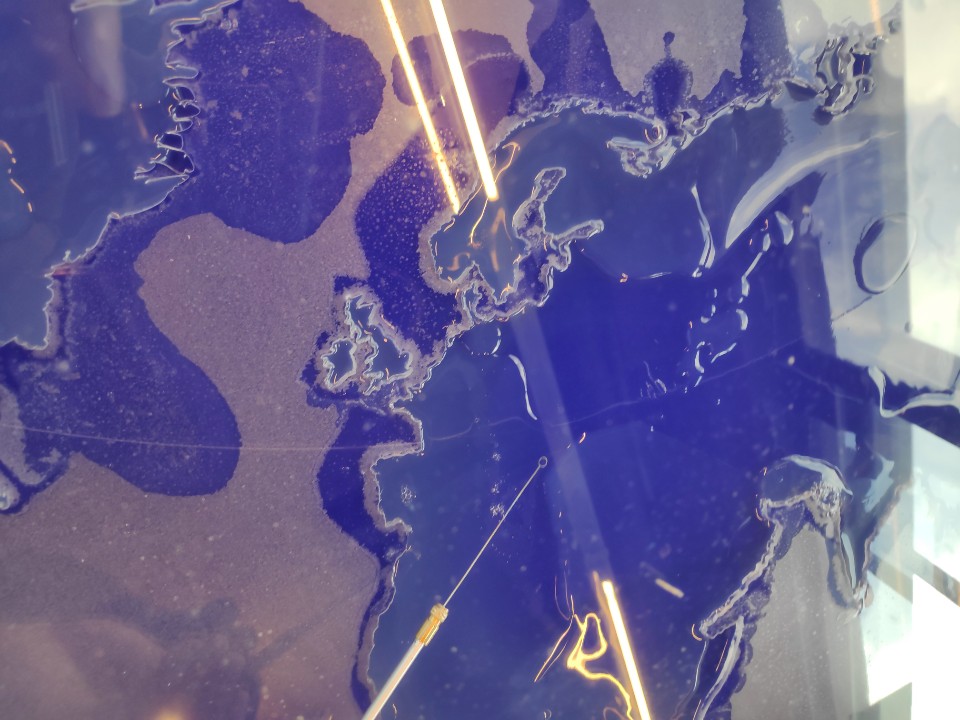

As for the microbes, I wanted to have at least 5 or 6 different sources with a plot twist. So I figured since we’re already drawing on the world, why not use that concept. I have some kimchi microbiome which are dominated by members of the Leuconostoc, Lactobacillus, and Weissella genera that I transplanted into the Korean penninsula. I did the same with other fermented foods like natto, worchester sauce, vegemite, apple cider, salami, kombucha, sauerkraut, kefir yogurt, raw cheese, and sugar cane. I also added some bacteria and molds already in the lab as well as to ensure growth as I am familiar with these growing im PCA agar so they will serve as a control. Lastly for the plot twist I added my radioactive tritium in the middle of Russia, because I already have it anyways bought from the previous plan preparation.

I really like its glow at night.

And so that’s my final project. I might not get my results by the time of the presentation but I am recording it at a time lapse so I will further update and present my findings on world domination.

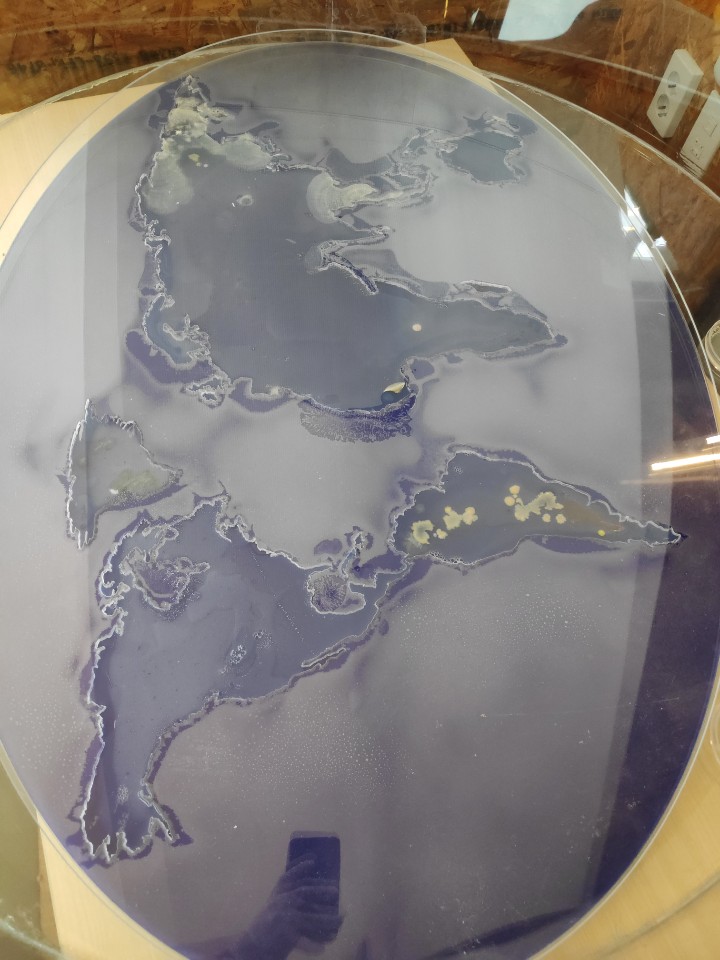

Edit: Well, unfortunately the raspberry pi camera setup suffered some kind of power outage and I never noticed it didn’t record. So I only have the few photos that I took every once in a while. Not to mention the top cover the the world seems to have bent somehow, either due to the moisture or some kinda of reaction to the medium. However I finally gotten some results. Several colonies of South America have developed as well as Greenland and the Eastern coast of Asia. It was interesting as some microbes were not expected to grow there so I expect some cross contamination must have occured, which seems both forunate and unfortunate as it still allowed growth and I was able to document them. Also, the tritium has shown to have effect as anything around it does not grow within a 4 ~ 5cm area around it.

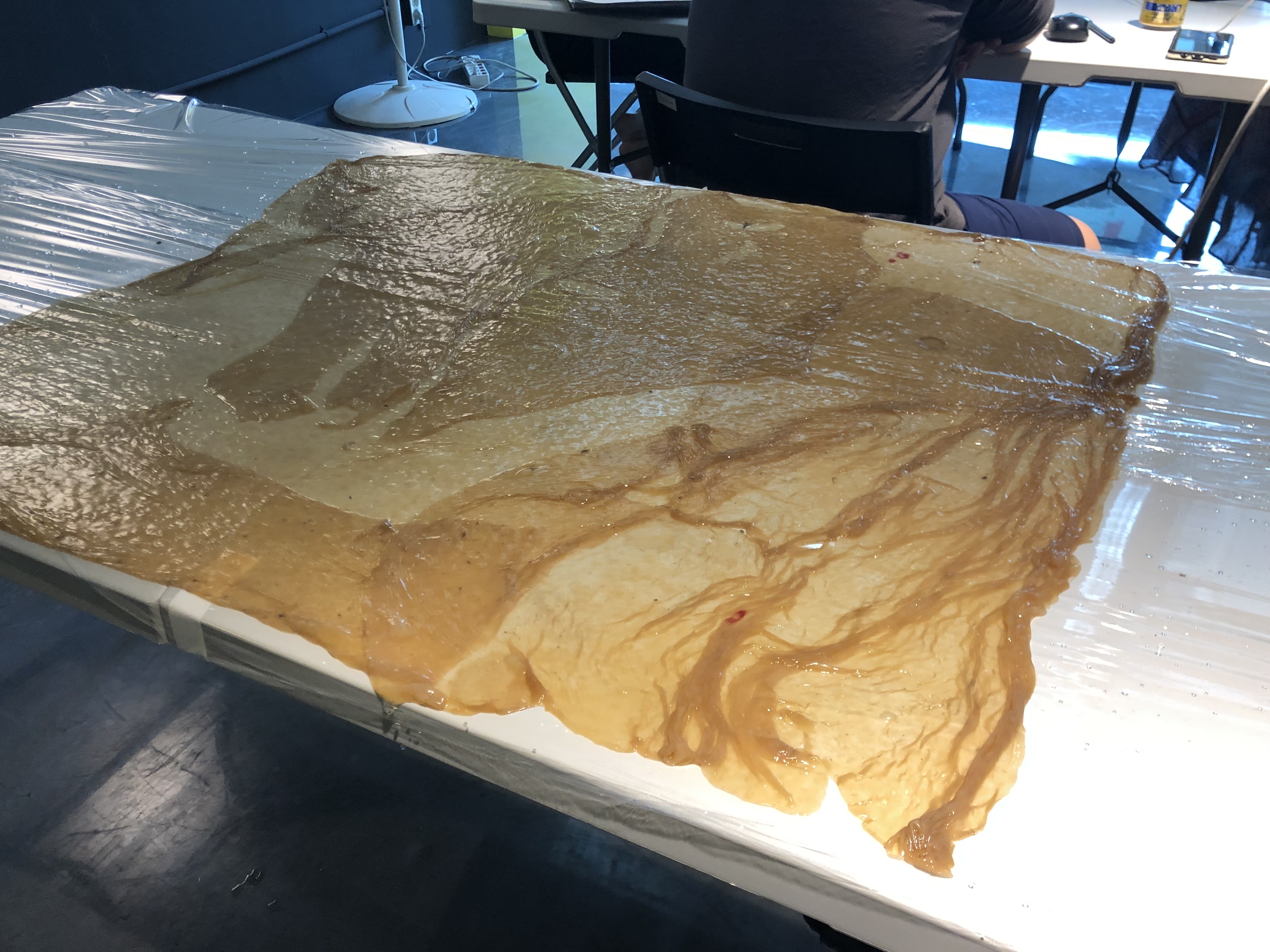

Edit2: We’ve done some further experiments like growing a giant kombucha leather sample, so we can make a big piece of artificial leather that we can fashion into other projects. Here are some pictures of it: